Achieving precise, brand-specific colors on EVA foam is critical for manufacturers across cosplay, sports equipment, packaging, and footwear industries. The Pantone Matching System (PMS) provides the universal language for color specification. Understanding which Pantone guide to reference based on your foam’s surface treatment is essential for accurate color matching.

Why Pantone is the Industry Standard for EVA Foam Colors

Pantone offers a globally recognized color system with precise numerical codes. This eliminates subjective descriptions like “sky blue” or “fire red,” ensuring consistent color reproduction across production batches and global supply chains. For EVA foam manufacturers, it provides:

- Reliable Communication: Clients specify exact Pantone numbers.

- Formula Accuracy: Laboratories create precise pigment formulations for each unique code.

- Quality Control: Objective measurement against standards.

Choosing the Correct Pantone Guide for EVA Foam

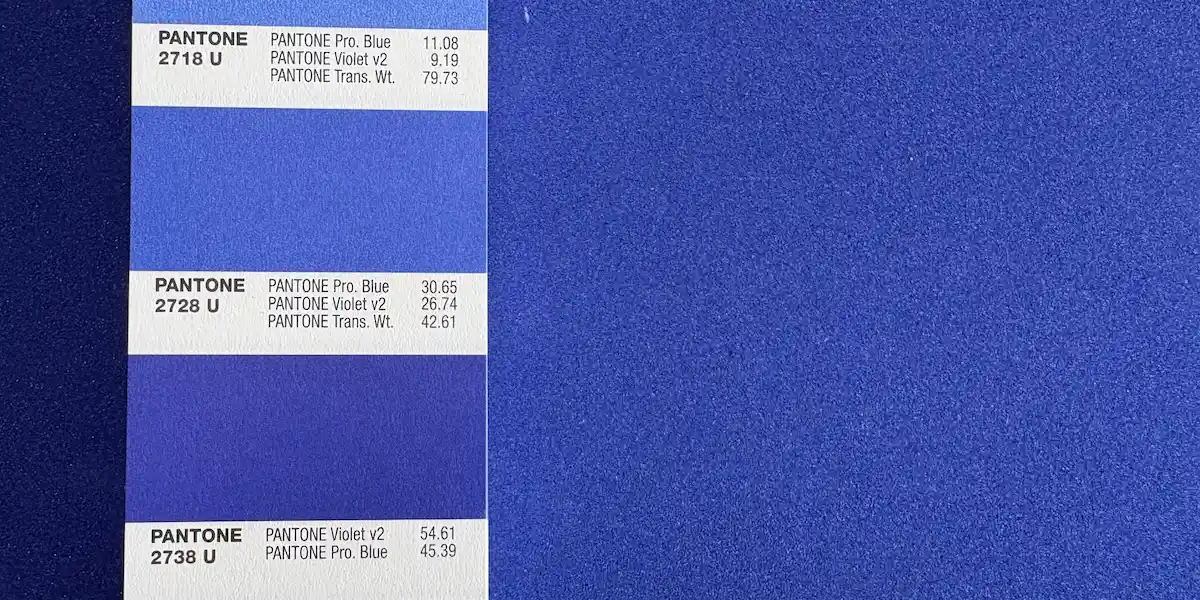

Your EVA foam’s surface finish dictates the correct Pantone guide:

- For Raw, Unprocessed EVA Foam Sheet:

- Use the Pantone Formula Guide Solid Uncoated.

- “Uncoated” simulates the natural, slightly absorbent surface of raw EVA foam. Colors appear slightly softer and less vibrant than on coated surfaces.

- For EVA Foam After Thermoforming or Heat Treatment:

- Use the Pantone Formula Guide Solid Coated.

- The heat process often creates a smoother, less porous surface layer resembling the “Coated” paper stock in the guide. Colors appear sharper and more saturated.

Crucial Tip: Always confirm with your client which Pantone guide (Solid Uncoated or Solid Coated) their color reference is taken from, and the surface state of their final product. Using the wrong guide leads to significant color variance.

The EVA Foam Color Customization Process

- Client Specification: Client provides the target Pantone number (e.g., PMS 185 C for coated, PMS 185 U for uncoated) and specifies the intended foam surface state (raw or thermoformed).

- Guide Selection: Manufacturer selects the corresponding Pantone Formula Guide (Solid Coated or Solid Uncoated).

- Formula & Compounding: The manufacturer uses the proprietary pigment formula associated with that specific Pantone number in the correct guide. Pigments are precisely measured and compounded into the EVA resin mixture before the foaming process.

- Production & Foaming: The compounded material undergoes the EVA foaming process (typically using chemical or physical blowing agents).

- Color Verification: The finished foam sheet or thermoformed part is checked against the specified Pantone guide under controlled lighting (D65 daylight standard).

- Instrumental Measurement (Critical QA Step): A spectrophotometer (color measurement device) is used to objectively measure the foam’s color and compare it digitally to the Pantone standard’s Lab values. This ensures numerical accuracy beyond visual assessment.

The Vital Role of Color Measurement Equipment

Visual checks under proper lighting are important, but instrumental measurement using a spectrophotometer is non-negotiable for quality assurance. This device:

- Quantifies color in the CIE Lab color space.

- Provides Delta-E (ΔE) values indicating the numerical difference between the sample and the standard.

- Removes subjective human perception from the final pass/fail decision. (Learn more about color measurement fundamentals on ColorScience.org)

Achieving Your Perfect EVA Foam Color

Precision EVA foam color customization hinges on three pillars:

- Correct Pantone guide selection based on surface finish (Uncoated for raw, Coated for thermoformed).

- Expertise in color compounding and EVA foam processing.

- Rigorous Quality Control using spectrophotometry.

Ready to specify your custom EVA foam color? Provide your Pantone number (stating Coated or Uncoated) and surface requirements, and leverage expert manufacturing for perfect color matches every time. (Explore the official Pantone guides at Pantone.com)

Frequently Asked Questions (FAQ)

Q: Why are there different Pantone guides (Uncoated vs. Coated) for EVA foam?

A: The surface texture significantly impacts how light interacts with color. Raw EVA foam has a more porous, matte finish similar to uncoated paper, making colors appear less intense. Thermoformed EVA often develops a smoother, slightly sealed surface akin to coated paper, resulting in richer, more vibrant colors. Using the matching guide ensures the pigment formula compensates for this optical effect.

Q: What happens if I specify a “Coated” Pantone for raw EVA foam?

A: The final color on the raw foam will likely appear duller, less saturated, and potentially darker than intended. The Coated formula is designed for a smoother surface that reflects more light intensely. Conversely, using an “Uncoated” Pantone for thermoformed foam might result in a color that is too bright or intense.

Q: How important is the thermoforming/heat treatment step for color?

A: It’s crucial. The heat applied during forming can subtly alter the foam’s surface structure and polymer alignment, affecting its light reflectance. This is the primary reason for switching from the Uncoated guide (for raw) to the Coated guide (for formed).

Q: Can you match any Pantone color on EVA foam?

A: While the Pantone system offers a vast range, perfect matches depend on the specific pigments’ compatibility with the EVA foaming chemistry and process limitations (temperature, additives). Most standard colors are achievable, but highly specialized effects (metallics, neons) might be challenging or impossible. Always discuss complex colors with your manufacturer.

Q: Why is a spectrophotometer necessary if we have the Pantone swatch?

A: Human vision is subjective and influenced by lighting and fatigue. A spectrophotometer provides an objective, numerical measurement (Delta-E) quantifying how close the foam color is to the Pantone standard. This is essential for consistent quality control, especially across batches and for meeting strict client tolerances.