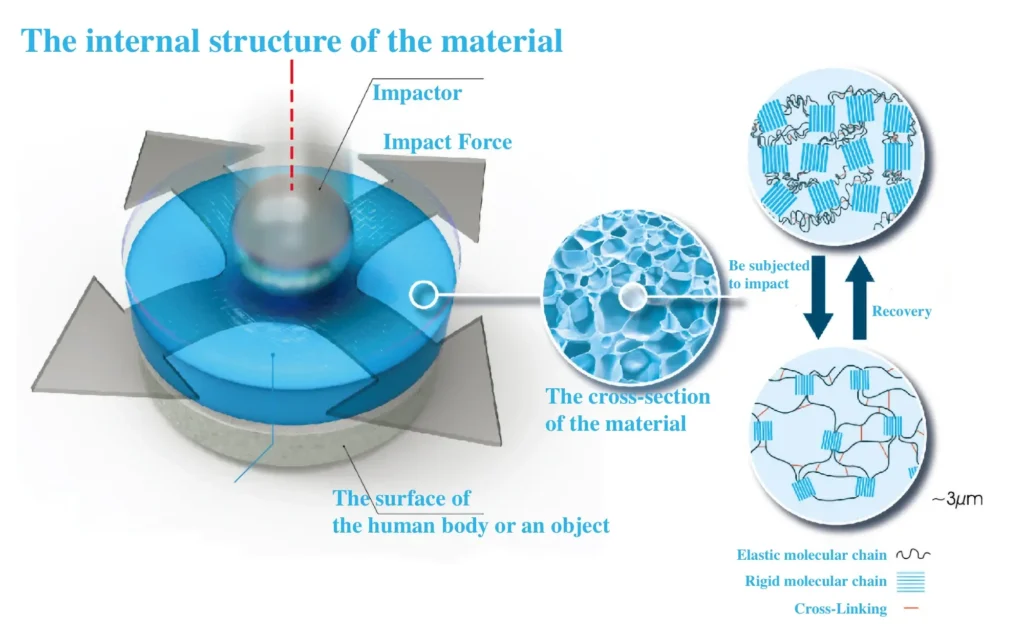

Vegetable oil-based open-cell foamed polyurethane(VOOF-PU) is an outstanding material. Created from vegetable oil derivatives and polyurethane technology, it features an open-cell structure, granting remarkable breathability. What sets it apart is its employment of biomimetic technology, inspired by nature’s shock absorption mechanisms. This enables it to absorb a staggering 97% of impact forces. When pressure or shock hits, the foam cells adeptly compress and dissipate energy.

Alias: Polyurethane Foam, PU Foam, Polyurethane Cellular Foam, Rigid Polyurethane Foam, Flexible Polyurethane Foam, PU Foam Board, Polyurethane Insulation Foam, Polyurethane Sponge, Polyurethane Padding, Closed-Cell Polyurethane Foam, Open-Cell Polyurethane Foam, PU Foam Cushioning, Polyurethane Foam Rubber, PU Foam Sheets, PU Foam Blocks

This page features only a fraction of our extensive product range. We encourage you to reach out to us via email to obtain our comprehensive product catalog.

Introduction

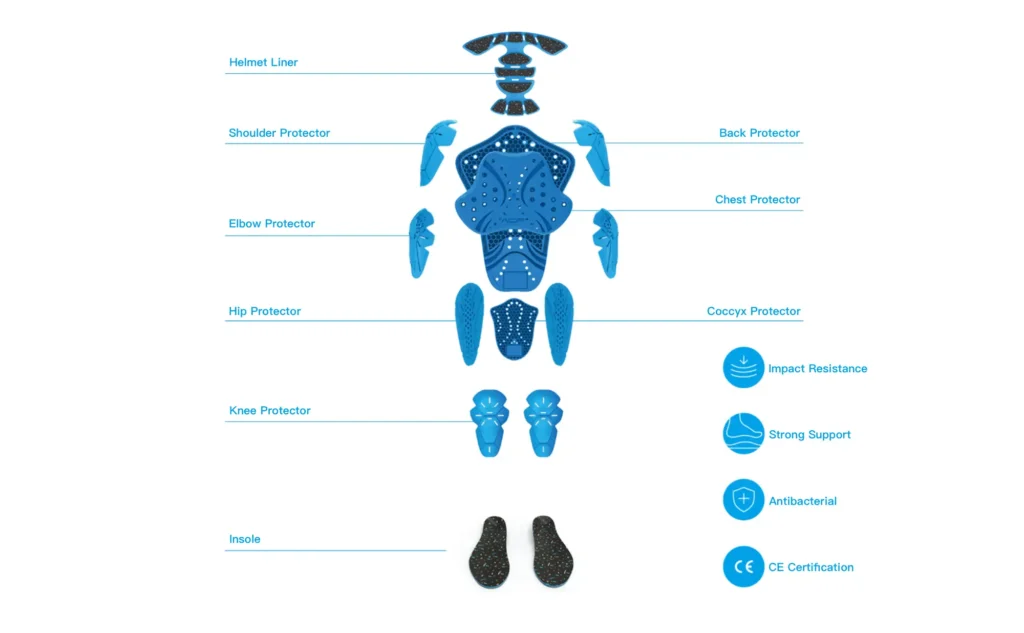

VOOF-PU is a kind of Vegetable Oil-based Open-cell Foamed Polyurethane cushioning and shock-absorbing material, which is covered by vegetable oil-based modified, polyether, polymer polyol, and a variety of additives and isocyanate mixtures prepared by a specific process. The material has the advantages of high cushioning (absorbing more than 70% – 90% of the impact), good air permeability (open pore structure), low permanent deformation rate (less than 5%), high thermal and dimensional stability, etc., and is widely used in a variety of fields such as human body protection (shoes, protective gear), drop protection (packaging of electronic products), automobiles (vibration and crash prevention), military, police and civilian equipment (bulletproof and impact resistance), medical care (vibration and shock protection), and construction (vibration of floors and walls).

Industrial Vibration Reduction

Technical Preview

The efficient buffering capacity of VOOF PU (Vegetable Oil-based Open-cell Foamed Polyurethane) material is based on the internal molecular flow technology. That is, the material usually shows soft and comfortable characteristics, but at the moment of being subjected to a strong impact force, it will absorb energy due to molecular flow and convert kinetic energy into insignificant thermal energy, thereby achieving the effect of dissipating the impact. Through a large number of experiments, this plant-based modified material has been successfully developed. It has a three-dimensional ultra-microstructure buffering and energy absorption technology. The material prepared with this technology can absorb more than 90% of the impact force and instantly convert the impact energy into insignificant thermal energy.

Characteristic parameter table of the WTSHLZ series

| Performance indicators | Test Standard | WTSHLZ13 | WTSHLZ18 | WTSHLZ28 | WTSHLZ38 | WTSHLZ48 | WTSHLZ58 |

|---|---|---|---|---|---|---|---|

| Density, kg/m³ | ASTM D3574-17 TEST A | 130 | 180 | 280 | 380 | 480 | 580 |

| Thickness, mm | Tolerance 10% | 2-45 | |||||

| Hardness, ASKER C | ASTM D2240-15 15S exposure at room temperature | 6 | 10 | 22 | 30 | 30 | 45 |

| Hydrolysis Resistance | ASTM D3574-17 TEST J | Good resistance to hydrolysis | |||||

| Compression Deformation, MAX% | ASTM D3574-17 TEST J | 10 | |||||

| Resilience, % | GB/T 6670-2008 | 10 | |||||

| Dermal Contact | ISO 10993-10 | PASS | |||||

| Tear Strength, MIN N/mm | ASTM D624-00 Die C | 1.5 | 1.8 | 2.0 | 3.0 | 4.0 | 6.0 |

| Tensile Strength, MPa | ASTM D412-16 TEST A Die C | 0.25 | 0.3 | 0.5 | 0.8 | 0.9 | 1.2 |

| Elongation at Break, MIN % | ASTM D412-16 TEST A Die C | 120 | 140 | 140 | 140 | 140 | 160 |

| Solvent Resistance | GB/T 11547-2008 Anhydrous ethanol immersion for 1 week | No discoloration or surface degradation | |||||

| Chemical Restriction Requirements | In accordance with Adidas A01, RoHs2.0, REACH SVHC latest standards | PASS | |||||

| Antimicrobial properties | GB/T 2881-2013 | PASS | |||||

Applications of different models of the WTSHLZ series.

A wide range of application fields

It can be as soft as cotton and as hard as a stone. Resistant to impact and resistant to compression deformation.

Soft

Lightweight

Energy absorption

Buffering

WTSHLZ18

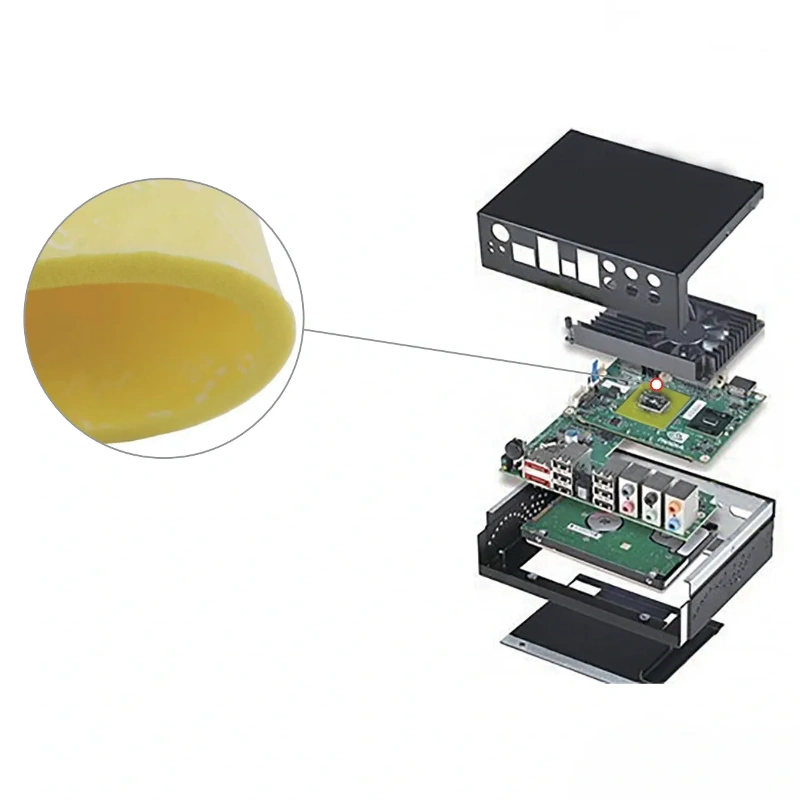

Yoga mat Home cushion Protection of electronic components Lining protection for valuable items Lining protection for luggage and bags

Soft

Lightweight

High-performance

protection

WTSHLZ28

Mid-strength sports shoe soles Yoga mats Home seat cushions Lining protection for valuable items Lining protection for luggage and bags

Efficient buffering

Comfortable

Stable

–

WTSHLZ38

Professional sports shoes insoles

Medical insoles

Yoga mats

Home seat cushions

Sports protective gear

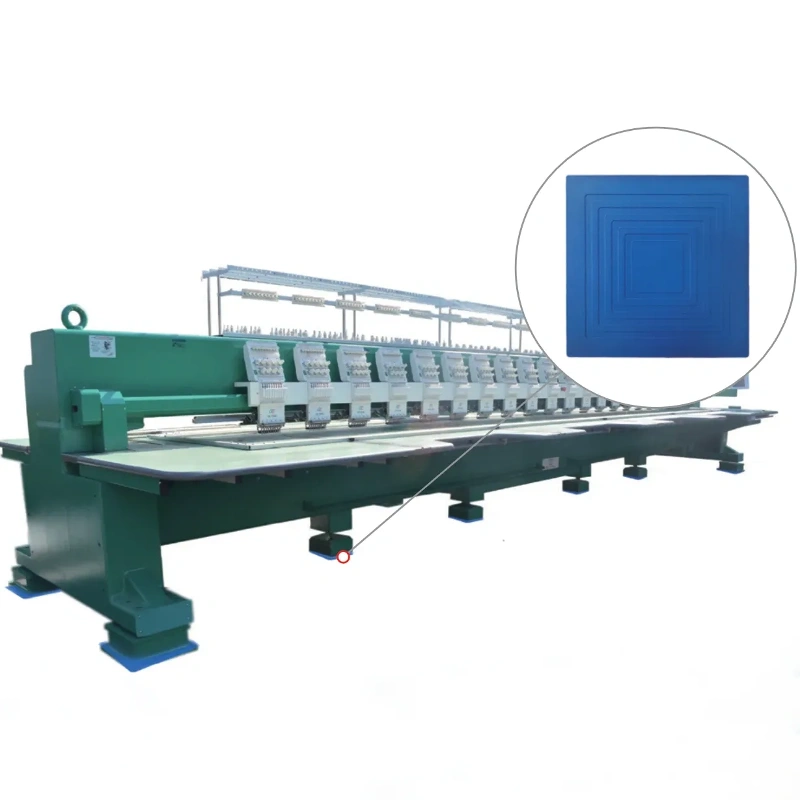

Industrial shock absorption pads

Efficient buffering

Durable

Stable

–

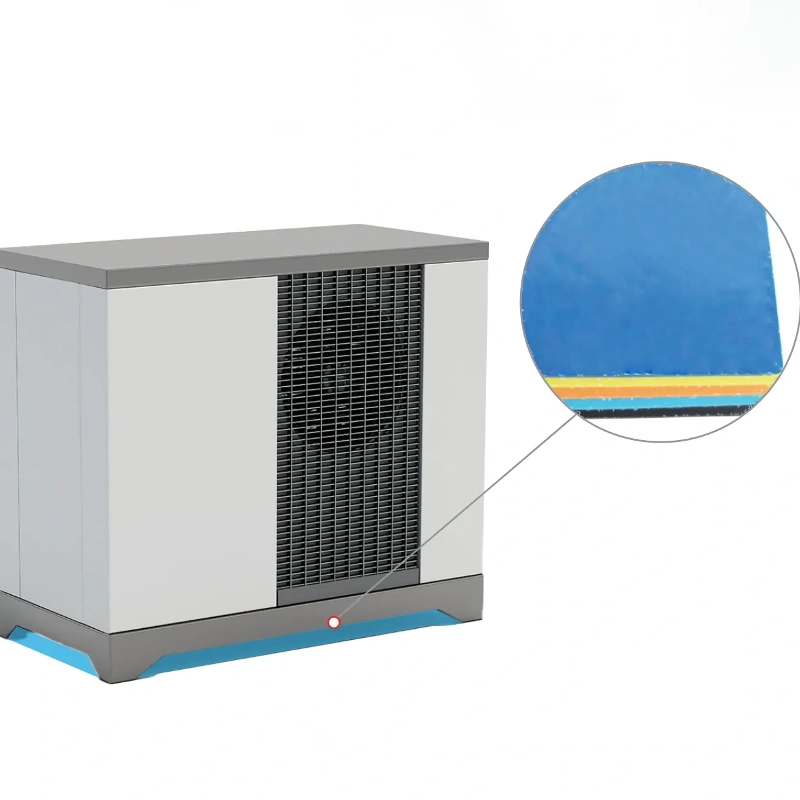

WTSHLZ48

Protective gear for extreme sports

Shock-absorbing pads for household appliances

Shock absorption for automotive batteries

Bumper anti-collision pads

Efficient buffering

Compression

-resistant

Stable

WTSHLZ58

Extreme sports

Medical insoles

Shock absorption for household appliances

Shock absorption for industrial equipment

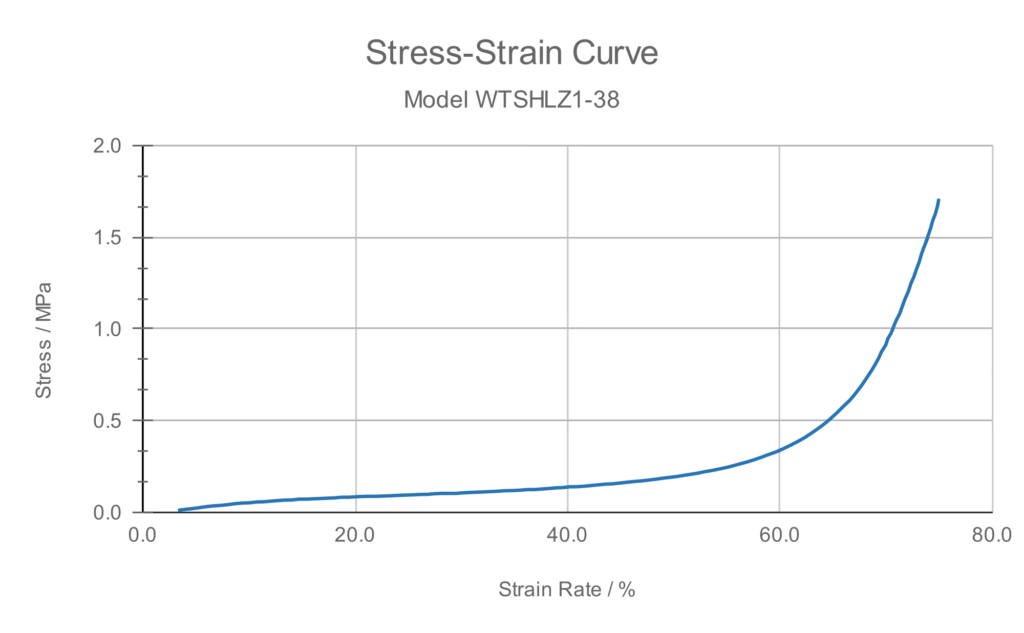

The performance curve of model WTSHLZ1-38

According to the stress-strain curve shown in the figure, it can be seen that the WTSHLZ1-38 model material has good mechanical properties. In the initial stage, the material shows linear elastic properties, and the stress increases linearly with the increase of strain. With the further increase of strain, the material enters the plastic deformation stage, and the stress growth rate gradually slows down. It is worth noting that near a strain rate of about 60%, the material begins to show obvious stress hardening characteristics, and reaches a maximum stress value of about 1.8 MPa at a strain rate of 80%, showing a strong resistance to deformation.

In general, this material has good linear elastic properties and can also withstand high stress under large strains, and is suitable for occasions that need to withstand large stresses and strains.

Gallery of products and applications

FAQs

Can I obtain samples? How can I obtain samples?

You can obtain samples. Please consult our sales staff for details. You can purchase some small-sized material samples at a very low price for your testing. We offer samples of different thicknesses. Generally, the size of the samples is approximately the size of an A4 paper.

What are the main advantages of VOOF-PU materials?

The VOOF-PU series materials have efficient anti-impact and anti-compression deformation performance, high rate sensitivity, being soft at low speed and rigid at high speed. The performance is stable, fatigue-resistant and high-temperature deformation-resistant. It is safe and environmentally friendly, free of four halogens and meets the requirements of Rohs 2.0. The design life is up to 10 years. It can be in sheet or roll form, easy to produce and punch, and can bring values such as extreme protection, enhanced damping, cost reduction and upgrade assistance to enterprises.

How to choose the models of WTSHLZ series materials?

If it is used for the protection of fragile and valuable items and electronic products, such as the protection of electronic components and the inner lining of fragile and valuable luggage, the WTSHLZ13 series can be selected; if it is used for the protection of fragile and valuable boxes, the inner lining of luggage and the protection of household seat cushions, the WTSHLZ18 series is more suitable; for medium-strength sports insoles, household protection pads and the inner lining of luggage, the WTSHLZ 28 series is applicable; for professional sports insoles, protective gear, helmets and the protection of household seat cushions, the WTSHLZ38 series can be considered; for the vibration and noise reduction of small household appliances and the protection of new energy vehicle battery packs, the WTSHLZ48 series is recommended; for extreme sports shoe materials, the vibration reduction of small household appliances and industrial equipment, the WTSHLZ58 series is suitable.

Where is VOOF-PU material better than traditional buffer materials?

In terms of compression performance, in the CFD 25% Kpa test, the range of the WTSHLZ series is 4 – 1000, which is better than ordinary high-density foam (25 – 500) and EVA (30 – 300), etc.; in terms of the compression set rate, the WTSHLZ series is only 10%, much lower than PEBA (45%), TPEE (49%), ETPU (40%), EVA (48%); in terms of heat resistance temperature, the WTSHLZ series reaches 125 degrees, which is higher than PEBA, TPEE, ETPU (all 60 degrees) and EVA (70 degrees); in terms of energy absorption ratio, the WTSHLZ series is more than 90%, higher than other compared materials (PEBA 40%, TPEE 30%, ETPU 35%, ordinary high-density foam 45%, EVA 40%).

Can the WTSHLZ series materials be customized?

Yes, they can. You can tell our salesperson your customization requirements such as size, color and packaging, and we will communicate product-related matters via email.

What are the performance indicators of each model of the WTSHLZ series materials?

- WTSHLZ13 series: Density 130kg/m², thickness 2 – 45mm, hardness ASKER C is 6, good hydrolysis resistance, the maximum compression deformation is 10%, the rebound performance is 10%, the skin contact passes the test, the minimum tear strength is 1.5N/mm, the minimum tensile strength is 0.25MPa, the minimum elongation at break is 120%, the minimum volume resistance is 10¹³Ω・cm, the flame retardant grade is HBF, the total maximum content of the four halogens is 50mg/kg, good solvent resistance, and it passes the restricted use requirements of chemical substances and the antibacterial performance test.

- WTSHLZ18 series: Density 180kg/m², thickness 2 – 45mm, hardness ASKER C is 10. Other performance indicators are similar to the WTSHLZ13 series. The minimum tear strength is 1.8N/mm, the minimum tensile strength is 0.3MPa, and the minimum elongation at break is 140%.

- WTSHLZ28 series: Density 280kg/m², thickness 2 – 45mm, hardness ASKER C is 22. The performance indicators are similar to the WTSHLZ13 series. The minimum tear strength is 2.0N/mm, the minimum tensile strength is 0.5MPa, and the minimum elongation at break is 140%.

- WTSHLZ38 series: Density 380kg/m², thickness 2 – 45mm, hardness ASKER C is 30. The performance indicators are similar to the WTSHLZ13 series. The minimum tear strength is 3.0N/mm, the minimum tensile strength is 0.8MPa, and the minimum elongation at break is 140%.

- WTSHLZ48 series: Density 480kg/m², thickness 2 – 45mm, hardness ASKER C is 30, the maximum compression deformation is 10%, the rebound performance is 10%, the skin contact passes, the minimum tear strength is 4.0N/mm, the minimum tensile strength is 0.9MPa, the minimum elongation at break is 140%, the maximum compression permanent deformation is 5%, the maximum thermal conductivity is 0.08W/(m・K), the minimum volume resistance is 10¹³Ω・cm, the flame retardant grade is VO, and it passes the restricted use requirements of chemical substances and the antibacterial performance test.

- WTSHLZ58 series: Density 580kg/m², thickness 2 – 45mm, hardness ASKER C is 45. The performance indicators are similar to the WTSHLZ13 series. The minimum tear strength is 6.0N/mm, the minimum tensile strength is 1.2MPa, and the minimum elongation at break is 160%.