Elevate Your Projects with High-Quality TPE Foam Solutions

Get Started with TPE Foam for Your Next Project!

Alias: Thermoplastic Elastomer, Thermoplastic Rubber, Thermoplastic Elastomer Rubber, Thermoplastic Vulcanizate, TPR (Thermoplastic Rubber), TPS (Thermoplastic Styrenic), TPU (Thermoplastic Polyurethane), TPO (Thermoplastic Olefin), TPC (Thermoplastic Copolyester), TPV (Thermoplastic Vulcanizate), SBC (Styrenic Block Copolymer)

TPE (thermoplastic elastomer) is a material that has the processing properties of thermoplastic and the elasticity of rubber.TPE materials can be plasticized at high temperatures, maintain a fixed shape after cooling, and soften and shape when heated again, so the processing method is similar to that of thermoplastic, and it is easy to be recycled and reused.

We use these TPE pellets to produce TPE foam sheets and customize and process them into a variety of TPE products.

TPE offers shorter vulcanization times and lower energy consumption than traditional vulcanized rubber, and does not require the use of harmful vulcanizing agents, making it more environmentally friendly in the production process.

TPE materials according to the chemical structure can be divided into several categories, such as styrene TPE (SBS, SEBS, etc.), polyolefin TPE (TPO, TPV, etc.), polyurethane TPE (TPU), and so on.

These materials are widely used in a variety of products in daily life, such as automobile parts, electronic products, medical equipment, shoes, toys, etc., mainly because they have good physical and mechanical properties, flexibility, chemical resistance and environmental protection.

TPE (thermoplastic elastomer) materials are known by several aliases, which are often based on their chemical structure, performance characteristics, or specific application areas. TPR, TPU, TPO, TPV, SBS, SEBS. they reflect the diversity of TPE materials and applications in different areas. Since TPE is a generic term for a large group of materials, different types of TPEs have different properties and applications.

TPE Foaming Process

- Batching: The proportions of different raw materials are prepared according to the formula calculated by the engineers.

- Mixing: The raw materials are thoroughly mixed and blended.

- Extruding: Extruding and weighing the semi-finished mass to obtain a standard weight mass.

- Foaming: Foaming the raw material mass into the specified size sheet after high temperature and high pressure.

Parameters of TPE sheet

We can customize the parameters of hardness, density, elasticity, tearing and so on as per customer’s requirement.

| Material | Hardness (Shore C) | Density (kg/m3) | Foam Rate | Water Absoprtion (%) |

|---|---|---|---|---|

| TPE | 15±5 | 110±20 | 25 | ≤1 |

| TPE | 25±5 | 110±20 | 20 | ≤1 |

| TPE | 35±5 | 140±20 | 20 | ≤1 |

| TPE | 45±5 | 180±20 | 15 | ≤1 |

Areas of application and products of TPE materials

TPE (thermoplastic elastomer) foam sheets are widely used in a number of fields and products due to their unique properties, such as light weight, flexibility, good resilience and abrasion resistance.

Insoles and shoe materials

TPE foam is commonly used to make shoe insoles, which can provide good foot support and shock absorption due to its good elasticity and comfort.

Cushioning and Packaging Materials

In the packaging of electronic products, home appliances and precision instruments, TPE foam sheets are used to provide cushioning and protection to reduce vibration and shock during transportation.

Seals and gaskets

Due to its excellent weatherability and chemical resistance, TPE foam is used as seals for doors, windows, automobiles and other mechanical equipment.

Sporting Goods

TPE foam is often used in sporting goods such as exercise mats, yoga mats, helmet interior liners, etc. to provide the necessary flexibility and protection.

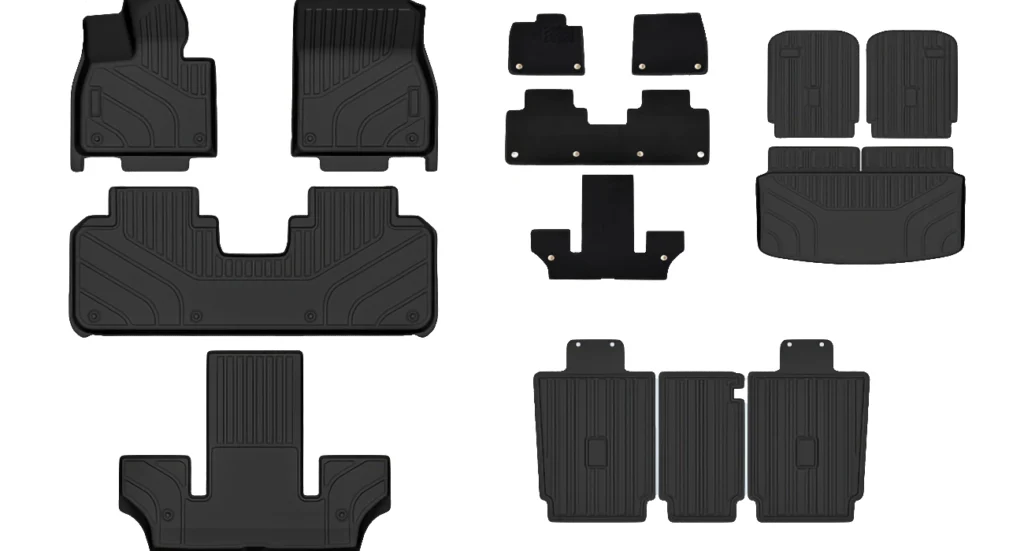

Automotive interiors

TPE foam can be used in automotive interiors such as door panels, dashboards, floors, and other components to enhance the texture and shock absorption properties of the interior.

Electronic accessories

used in the manufacture of electronic products such as grips, protective covers, keyboards and other components to provide a comfortable grip and good protection.

Sound insulation and sound absorption materials

TPE foam sheets have good sound insulation and sound absorption properties, and can be used for sound insulation and noise reduction in construction and transportation.

grips

In industrial applications, TPE foams are used as gaskets, pads and support materials to reduce vibration and noise.

Toys and children’s products

Due to its safety and flexibility, TPE foam is used in the manufacture of children’s toys and toddler products.

Green

ECO

Friendly

TPE materials are recyclable and can be recycled and reprocessed to reduce resource waste and environmental pollution.

Compared with traditional vulcanized rubber, TPE materials do not require the use of harmful vulcanizing agents, thus reducing the potential harm to the environment and human body.

TPE materials are easier and faster to process than thermoset rubber, thus saving energy and reducing production time.

TPE foam can be used to reduce environmental pollution by replacing traditional plastic materials such as PVC. This substitution helps to reduce environmental pollution while maintaining or enhancing product performance.

Request Free Samples

Experience Our Products, Your Way

Avail yourself of the opportunity to test our premium samples free of charge. While the samples themselves are provided at no cost, we kindly request recipients to cover the shipping fees. This arrangement allows you to experience the quality and craftsmanship of our products firsthand, ensuring confidence in your wholesale orders. Contact us today to request your complimentary samples and explore the excellence of our products while shouldering only the shipping expenses.